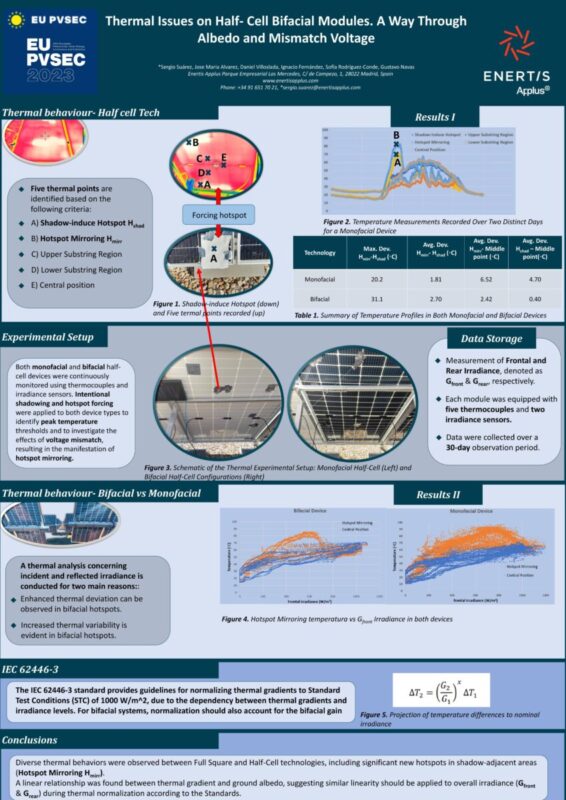

Scientists in Spain tested PV modules under partial shading conditions, aiming to better understand the formation of performance-damaging hotspots. The study reveals a potential issue particularly affecting half-cell and bifacial modules, which may cause accelerated performance loss and is not covered by current testing/certification standards.

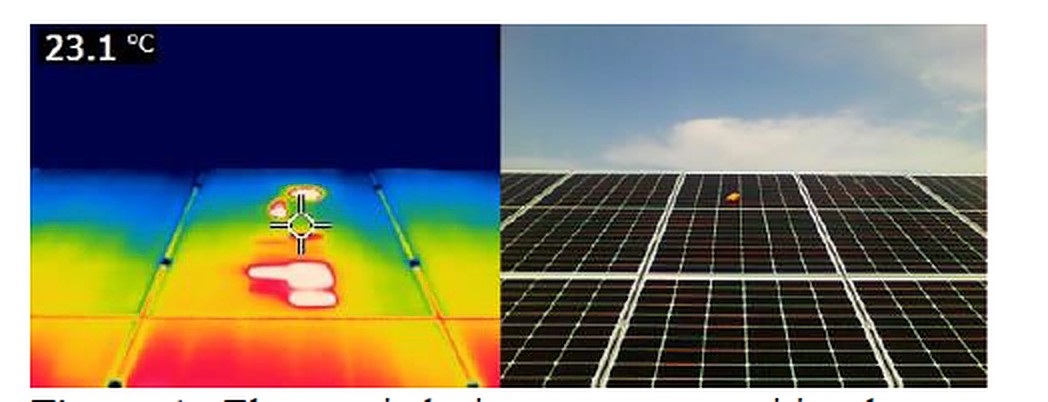

In the study, solar panel modules were intentionally shaded to induce hotspots.

Cutting silicon cells in half, and making them able to generate electricity from sunlight hitting both sides, are two innovations that brought the possibility of increased energy yield at little extra production cost. Consequently, both of these have grown rapidly over the past few years, and now represent the mainstream in solar cell and module manufacturing.

New research, which was among the winners of a poster award at the EU PVSEC conference held in Lisbon last month, has demonstrated that the combination of half-cut and bifacial cell designs may contribute to hotspot formation and performance issues, under certain conditions. And current testing standards, the study’s authors warned, may not be equipped to spot modules vulnerable to this type of degradation.

The researchers, led by Spain-based technical consultancy Enertis Applus, covered parts of a PV module to observe its behavior under partial shading. “We forced shadowing to take a deep dive into the behavior of monofacial and bifacial half-cell modules, focusing on hot spot formation and the temperatures these spots reach,” explained Sergio Suárez, global technical manager at Enertis Applus. “Interestingly, we identified mirrored hot spots that emerge in the opposite position with respect to normal hot spots without apparent reasons, like shadowing or breakages.”

Faster degradation

The study indicated that the voltage design of half-cell modules may cause hotspots to spread beyond the shaded/damaged area. “The half-cell modules presented an intriguing scenario,” continued Suárez. “When a hotspot emerges, the module’s inherent voltage parallel design pushes other unaffected areas to develop hotspots as well. This behavior could hint at potentially faster degradation in half-cell modules due to the appearance of these multiplied hotspots.”

The effect was also shown to be especially strong in bifacial modules, which reached hotspot temperatures up to 10 C higher than the single-sided modules in the study. The modules were tested over a 30-day period under high irradiance conditions, with both cloudy and clear skies. The study is soon set to be published in full, as part of the proceedings of the 2023 EU PVSEC event.

According to the researchers, these results reveal a route to performance loss that is not well covered by module testing standards.

“A singular hotspot on the lower part of the module might instigate multiple upper hotspots, which, if not addressed, could accelerate the module’s overall degradation through increased temperature,” said Suárez. He further noted that this could place additional importance on maintenance activities such as module cleaning, as well as system layout and wind cooling. But spotting the problem early on would be preferable to this, and require new steps in testing and quality assurance at the manufacturing stage.

“Our findings spotlight a need and an opportunity to re-evaluate and possibly update standards for half-cell and bifacial technologies,” said Suárez. “It’s essential to factor in thermography, introduce specific thermal patterns for half-cells and adjust the normalisation of thermal gradients to Standard Test Conditions (STC) for bifacial modules.”

Post time: Oct-17-2023